Valued Grain Chain

This Flagship Innovation Experiment uses technology to identify grain lots, define their quality and record cultivation history to improve business models of Nordic arable farmers.

Concept

To increase the profitability of cereal production, this Flagship Innovation Experiment (FIE) relies on the close cooperation of technology providers and farmers to develop a grain value chain, utilising and seamlessly integrating available digital solutions. Farmers produce grain utilizing novel technologies such as precision fertilizing, spraying, yield mapping, remote sensing, as seen feasible in the farm.

The work was started with co-creation actions between farms and consumers to understand better, what aspects will bring value to grain products in the near future. It seems that ecological aspects like carbon footprint and biodiversity in farms are valued, the nutritional value of grain, as well as the origin, proved to be important issues to consumers according to our qualitative study. To collect all information, we need to federate IT Systems and ensure that all data is collected into a single "Value Grain Chain".

These smart farming technologies can identify grain lots, define their quality, record cultivation history alongside origin, aggregate data about product information and link it to the grain lot in an electronic grain marketplace. Due to the relatively low average yields stemming from the climate conditions of the Nordic region, producing cereals in bulk is considered a low-profit business. Therefore, this FIE aims to develop business models focused on identifying valuable grain lots already in the field and realising their value in the electronic marketplace based on traceable product information. The variations in soils, cultivation methods, used inputs and farm sizes create additional obstacles when trying to characterise grain lots, introduce their true value to the market, find customers and logistically handle them. The digitalization of farms and smart agriculture has become a popular topic also in Nordic agriculture. However, despite farmers increasing interest in these techniques and the benefits they provide, investments in precision agriculture techniques have not paid off for farmers until now.

To align all stakeholders within the grain value chain and enhance the digitalisation, this FIE leverages the potential of Competence Centres (CCs) and Digital Innovation Hubs (DIHs) in the region to share best-practice examples, to connect farmers with national and international service providers and attract potential investments.

Implementation

The experiment involves 3 farms, 2 in Finland (Knehtilä and Similä) and 1 in Sweden (Hedåkers Säteri). One of the farms in Finland is an organic farm (Knehtilä Farm).

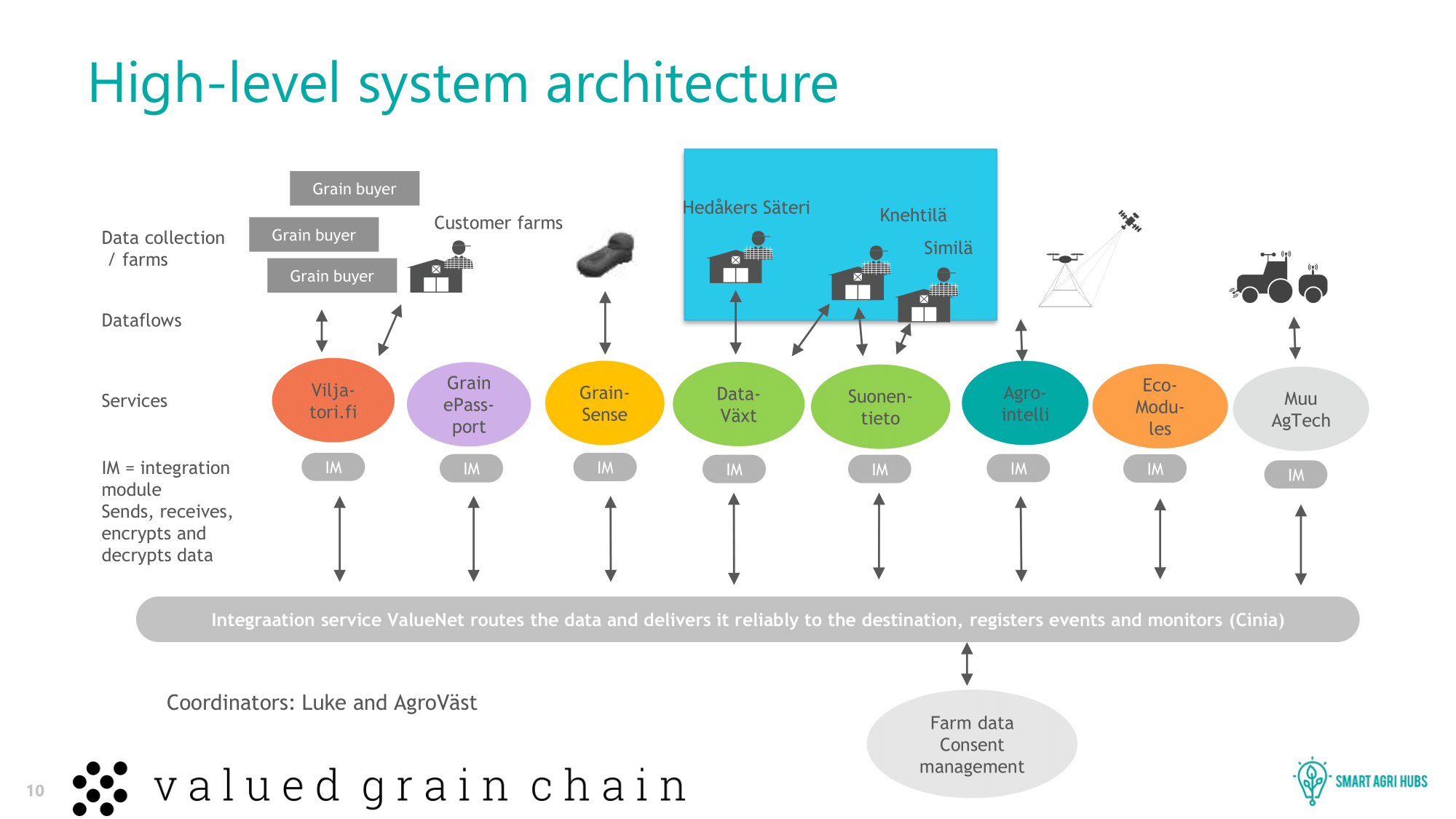

The main and most important achievement was the creating of a federated software infrastructure by integrating IT systems from different vendors in a third-party service, which enabled simple and agile data connections between them. The integrated IT systems formed a chain of digital technologies that farmers needed in order to run the digital grain chain. The experiment provided the first insight into a world of federated software infrastructure which creates the foundation for further development in collaborative systems. An important achievement was to showcase how farms can take ownership of the value chain of their production by taking the precision/smart farming data from farm operations to secondary use. The farmers take selected grain lots to the electronic grain marketplace (Suomen Viljakauppa/Viljatori.fi) to seek the best price for their products. With the Value Grain Chain, the buyer can trace the production chain back to the field through the linked identity code systems.

The objective was to implement the planned Valued Grain Chain as a federated software infrastructure by experiment partners, evaluate its usability and economic profitability by participating farms, and disseminate it to a larger group of farmers and other stakeholders. The preconception of the experiment was that well-planned integration and use of digital tools will improve the profitability of cereal production despite the investment needed in the equipment.

Lessons Learnt

The main challenge encountered was the coordination between different service providers. Service providers might not have the "big picture" in mind when it comes to sharing and federating IT systems. The compatibility of IT systems with the ones supported by other service providers is often not considered a top priority. The COVID-19 pandemic prevented team members to meet in person or demonstrating an application to farmers on site. The staff assigned to this experiment by several of the companies changed in several of the companies. The level of automation in data exchange between the IT systems could have reached a higher level if the ecosystem had been more stable.

The situation revealed that as an experiment orchestrator, we can inform, communicate and divide tasks between parties but we cannot influence a company's focus.